Case: WOOD

When trees are felled, logs are usually made from the trunks. However, much of the felled wood remains in the forest that could be processed into products for sale.

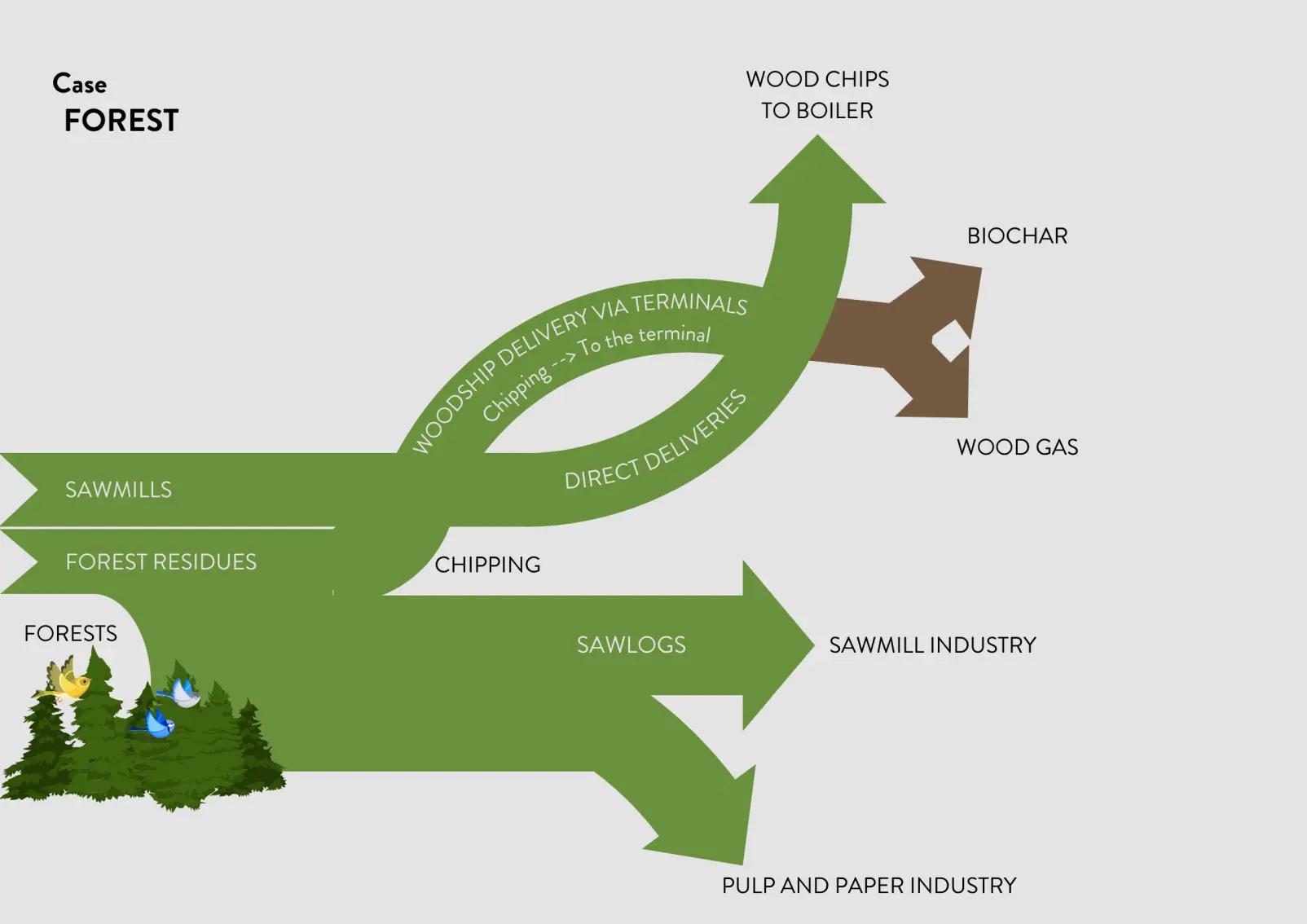

We are exploring how to turn the forest residues from wood harvesting and sawmill chips into products that are more profitable to sell than using wood for energy production. In particular, we will develop uses for wood material left in forests from felling, pruning and chipping.

Wood material can be used to make wood pellets and biochar, for example, and can be processed into more valuable products. Source: KristinaEco

The traditional mechanical forest industry processes wood into planks, plywood and chipboard, while the traditional chemical forest industry processes wood into pulp and paper. However, chemically speaking, all wood pulp consists of cellulose, hemicellulose and lignin. Through various techniques, wood other than trunks can also be processed into several valuable products.

Wood material can be processed into carbon-rich, solid biochar. There are many uses for it. It is suitable for soil improvement for all plants, from perennials to houseplants, because it improves the living conditions of beneficial micro-organisms and soil structure and provides nutrients to plants. Biochar can filter urban stormwater and nutrient-rich agricultural waters and even clean house air. Industry can utilise biochar for everything from making medicines to making batteries and textiles.

A wide range of extractives can also be separated from sawdust, bark, twigs, needles and other selected wood parts. The range of these biomaterials and their applications is enormous.

The hemicellulose in wood can also be broken down into sugars. Instead of being eaten, the sugars in wood can be processed into films, plastics, textiles and cosmetics for packaging. Industry can use products made from wood sugars as a substitute for materials made from oil pumped from the ground.

At present, wood chips and forest residues are mainly used for energy production, but biomass combustion is increasingly being replaced by renewable electricity. Thus, entrepreneurs who collect and supply wood chips are looking for new business.

In our project, forest machine entrepreneurs, researchers and industry work together to create new business. We have identified business opportunities with forest machine entrepreneurs. Researchers have developed product ideas used to design business with companies. Products and business opportunities are developed and tested in everyday situations.

Explore other case examples:

Case: POTATO

Usually, only the part of the potato that ends up on the dinner plate is used, even though a large amount of valuable components go to waste – broken potatoes, peels and other surplus are often composted or used as animal feed.

In the KristinaEco project, researchers, farmers and industry are working together to find more profitable ways to refine these side streams into biogas, biochemicals and soil improvers. This way, even unmarketable potatoes can generate profitable business.

Case: GREENHOUSE VEGETABLES

In greenhouse vegetable production, a large part of the plant mass – such as stems, leaves and turnips – goes unutilised, even though they contain many valuable substances.

In the KristinaEco project, researchers, growers and industry are working together to develop solutions to refine these plant side streams into biogas, biochemicals and soil improvers. The goal is to turn surplus biomass from a burden into profitable business.

Case: FISH

Usually, only fish fillets are used, even though scales, skin, bones and viscera also contain a wealth of valuable substances.

In the KristinaEco project, researchers, fish farmers and industry are working together to develop new ways to refine fish residues into products such as gelatine, proteins, fish oil and biogas. This way, previously wasted fish parts can produce new products and business – benefiting both people and the environment.

More information: